BMW I VISION CIRCULAR

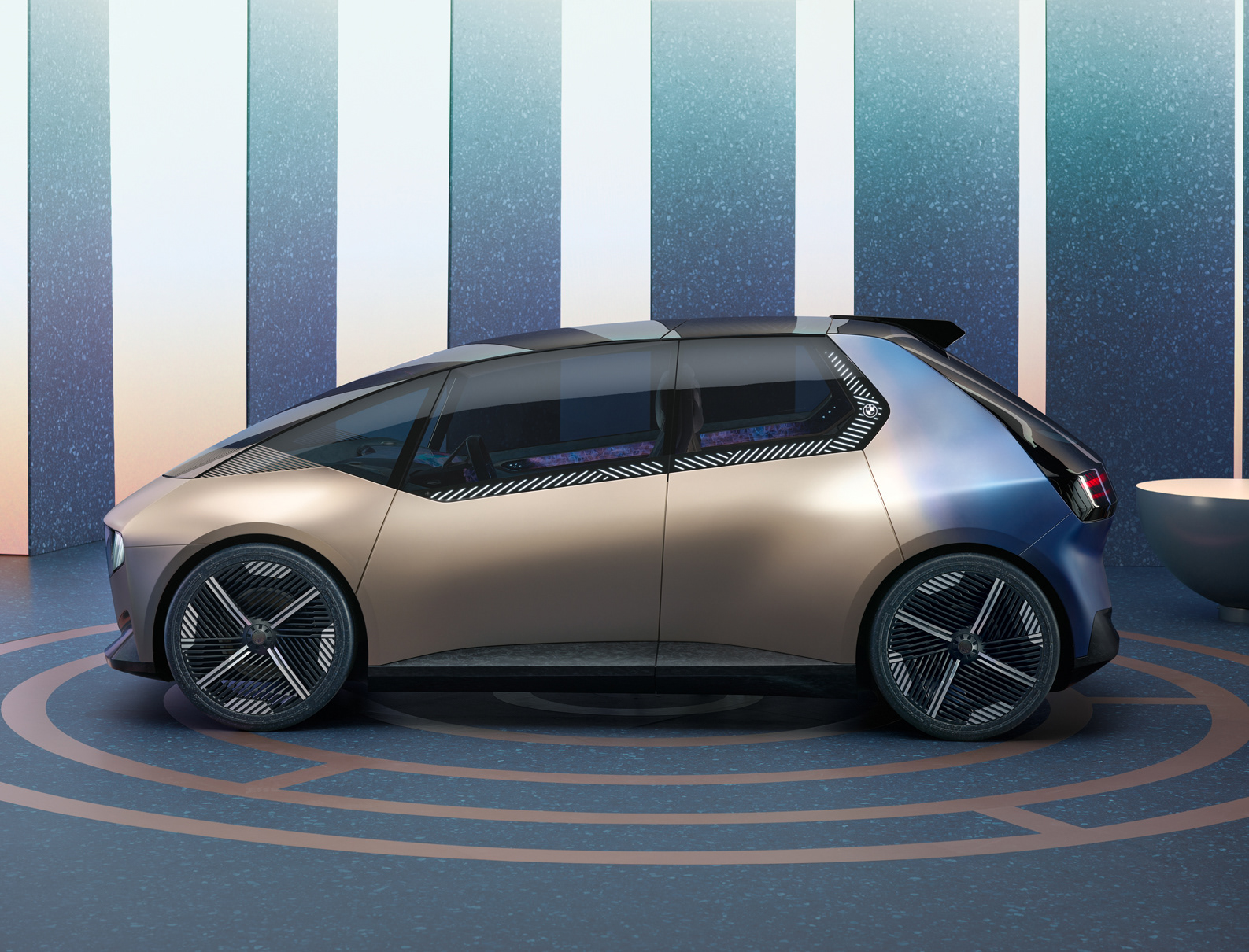

With the BMW i Vision Circular, the BMW Group is looking ahead to a compact BMW for the year 2040 that is focused squarely on sustainability and luxury.

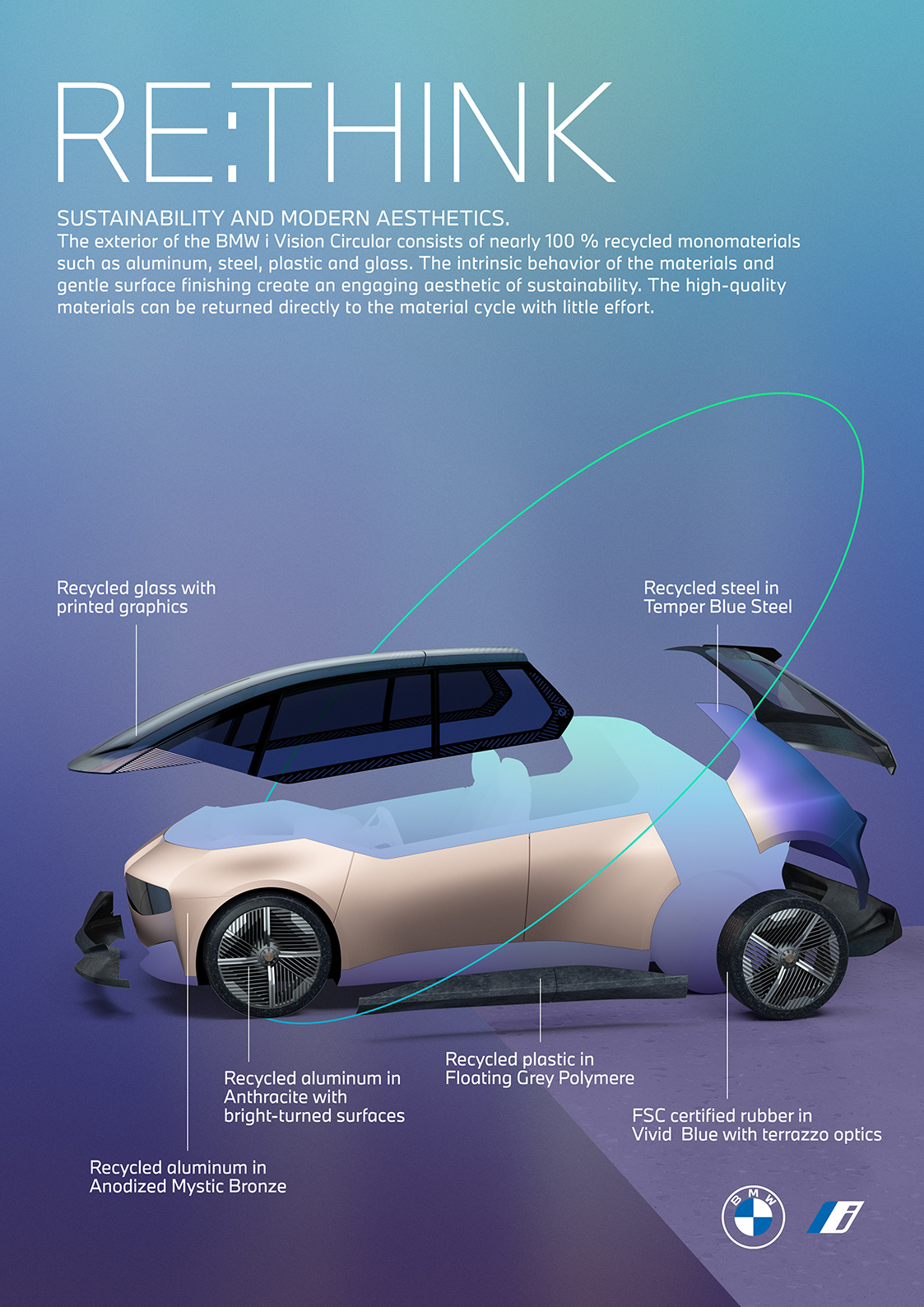

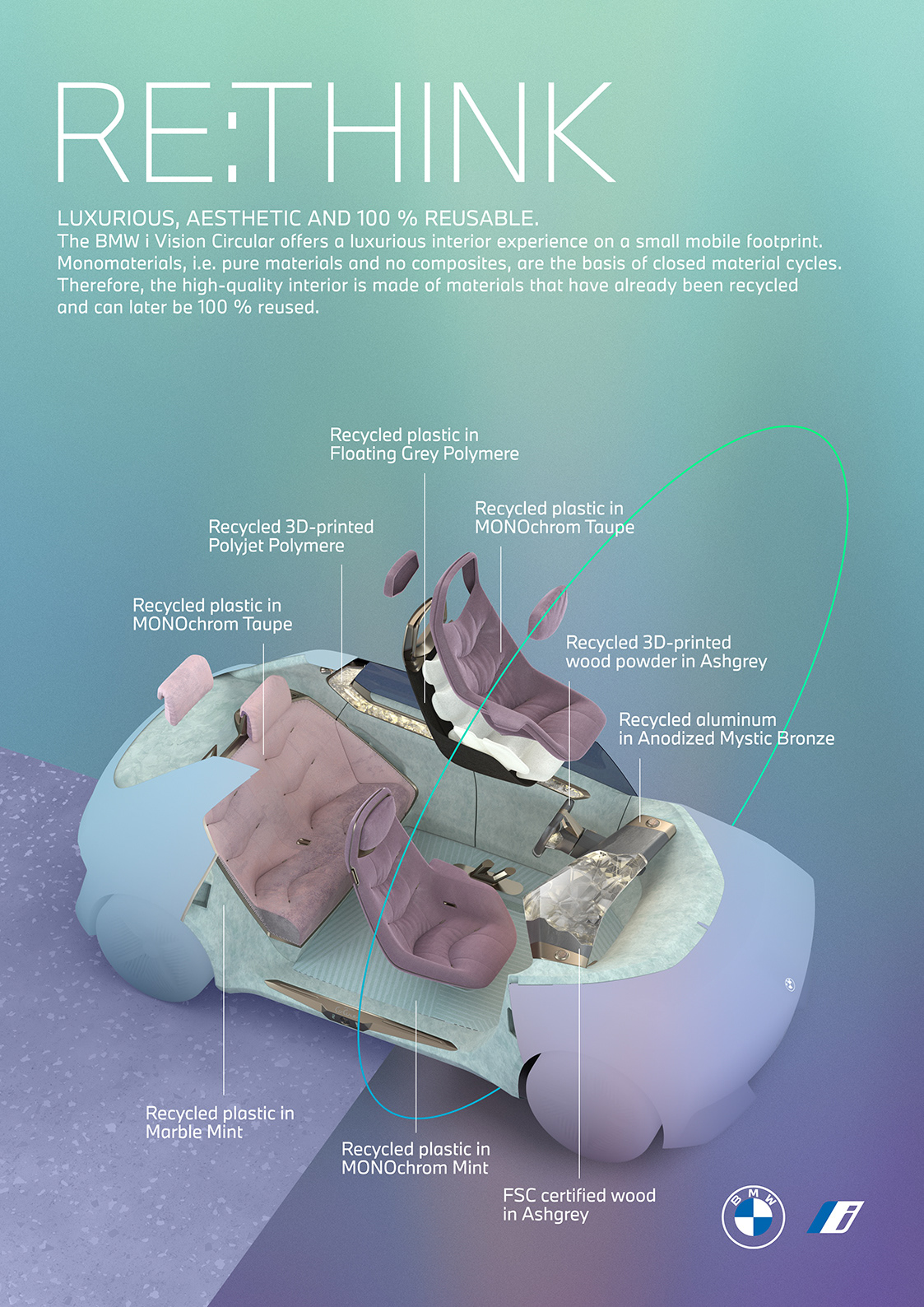

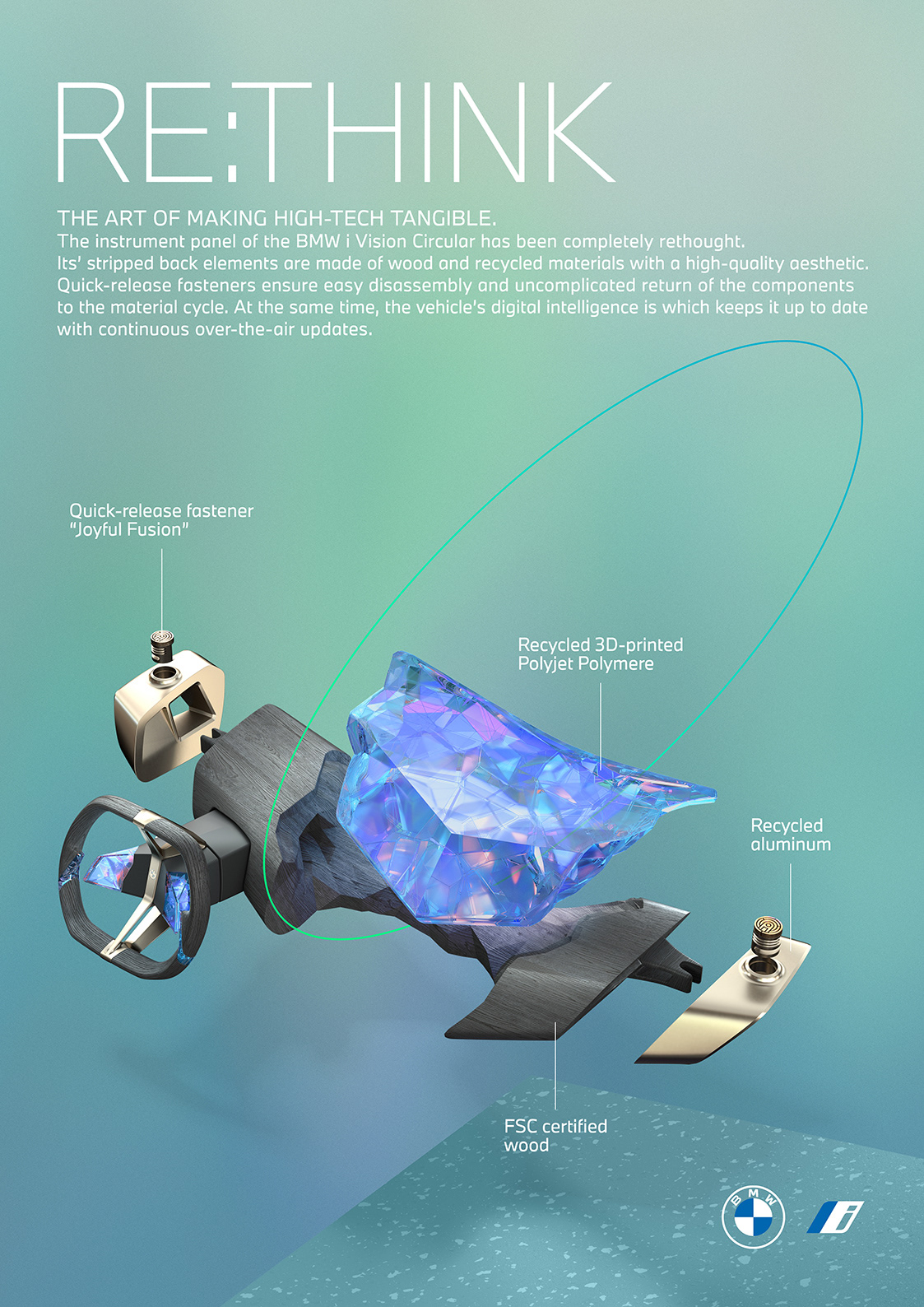

RE:THINK

Circular product design begins by thinking about things differently. For the BMW i Vision Circular this meant scrutinising processes and manufacturing technologies and thinking differently. The function performed by each component part up to now was examined, after which the part was removed without replacement or cleverly repackaged where appropriate and then designed to enable closed materials cycles.

RE:DUCE

“I do more with less” has long been an integral part of the BMW i philosophy. The BMW i Vision Circular demonstrates this through the rigorously applied reduction in the number of component parts, material groups and surface finishes, dispensing completely with exterior paintwork, leather and chrome, for instance. Materials from bio-based raw materials also help to minimise environmental impact and contribute to a smaller carbon footprint.

RE:USE

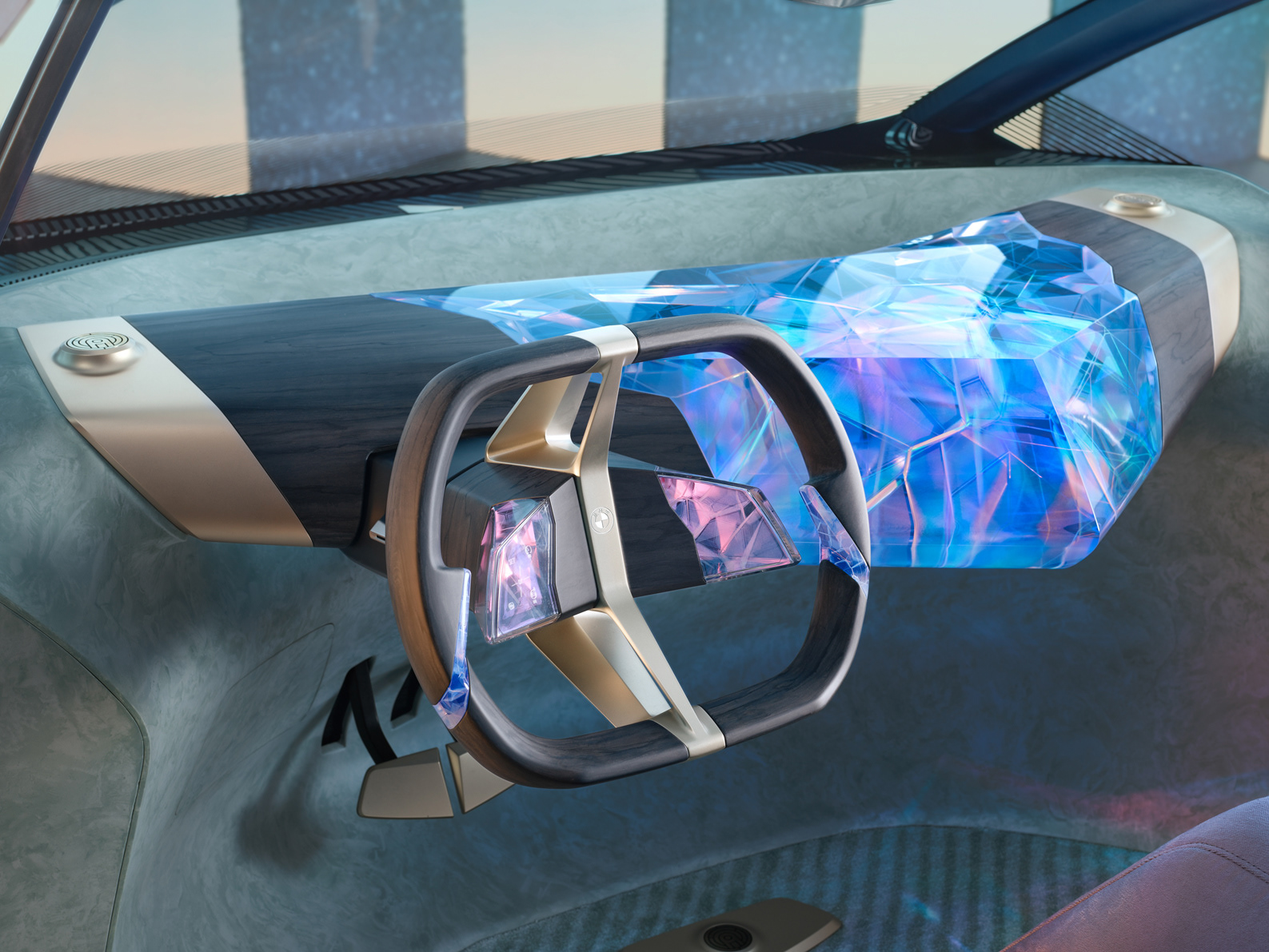

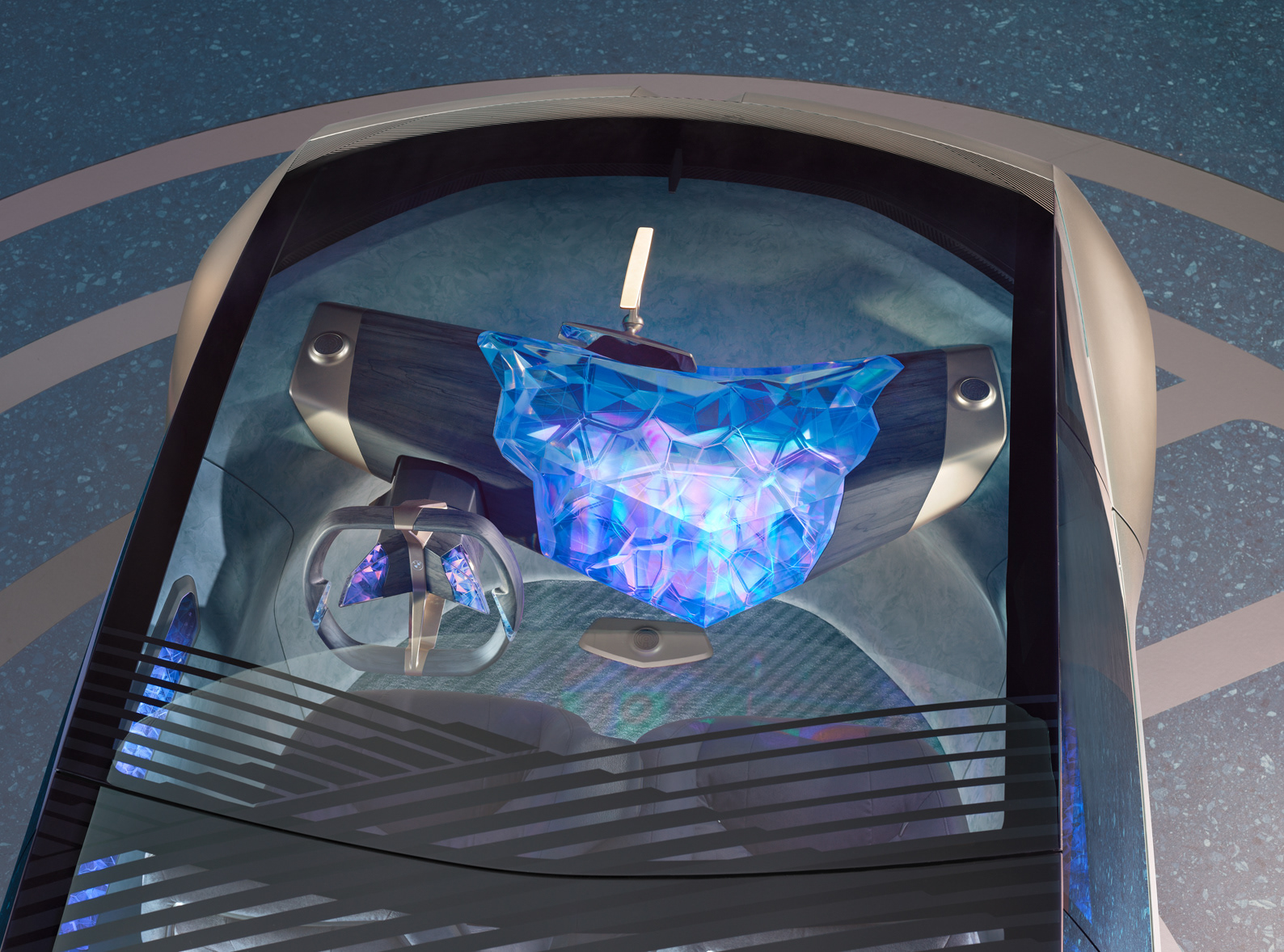

Ideally, a sustainable product will have a long lifespan, with a rich and enjoyable product experience making people a lot more enthusiastic about using the product – and using it for longer. One way of ensuring this happens is by incorporating digitality to create new experiences. The display options via digital display surfaces in the exterior and interior of a car and the availability of “option as a service” allow users to constantly bring something new to the vehicle. Constant updates over the air and cloud computing keep the product technically up to date for longer.

RE:CYCLE

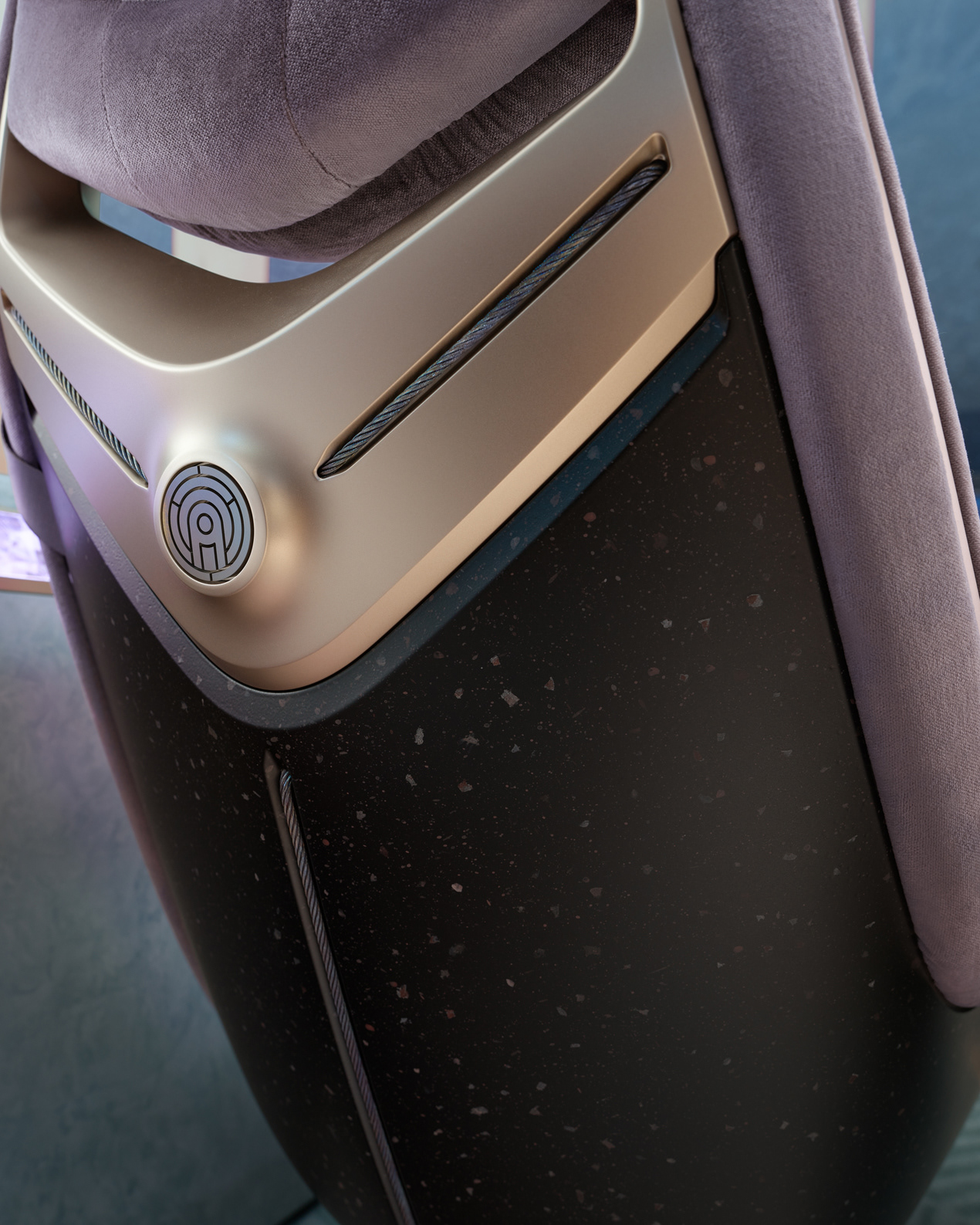

When it comes to the materials used, the focus with the BMW i Vision Circular is on recycled materials (“secondary first” approach) which are intended to be reused again at the end of the product life cycle. Having a small number of different mono-material groups with connections that can easily be undone is crucial for good recycling. For this reason, the BMW i Vision Circular avoids bonded connections or composite materials and uses intelligent types of connection, such as cords, press studs and quick-release fasteners, instead.

JOYFUL FUSION

The laser-etched graphic in the centre of the quick-release fastener is made up of the letters of the word “circular” arranged in the form of a circle. A special socket wrench separates the component parts joined by the fastener with a single rotation. The ‘joyful fusion’ fastener creates a theft-proof and stable connection and, at the same time, allows many component parts of the vehicle to be dismantled with just a single tool.

CIRCULATITY WITH CLEVER SOLUTIONS

In the front, two separate lounge seats with integral head restraints create an exclusive ambience. Their velvet-like upholstery is made from recycled plastic and is held within a light-gold aluminium frame. The seats rest on a slender mono-post base with fore/aft adjustment. The back of the slim front seat shells is made of recycled plastics with a terrazzo-look finish. Another circular ‘joyful fusion’ quick-release fastener for simple dismantling can be found here, allowing the metal and fabric to be easily separated and sorted, and then reused.

SMART MOBILITY

Data-based smart mobility for maximum efficiency in urban traffic. Another key measure in the drive towards sustainable urban mobility extends beyond the actual vehicle: making intelligent use of the available real-time and long-term traffic data for maximum mobility efficiency. CO2 emissions caused by stop-start traffic or even searching for a parking spot could be reduced significantly across a large number of users.

CIRCULAR DESIGN – A NEW APPROACH.

“We gave thorough consideration to circularity from the outset during the design process for the BMW i Vision Circular. As a result, this Vision Vehicle is packed with innovative ideas for combining sustainability with a new, inspirational aesthetic – we call this approach ‘circular design’,” explains Adrian van Hooydonk, Head of BMW Group Design. Circular design embraces the four principles of RE:THINK, RE:DUCE, RE:USE and RE:CYCLE.

CREDITS

Client: BMW Group, Munich, Germany

Creative Direction: Antje List, Hannes Ziesler

Project Team: Raphael Jasinski (Lead), Julia Obermeier, Anita Tauber, Ayhan Aydin, Till Jenninger

Head of Design Identity and Media: Hannes Ziesler

Thanks to: Fabio Olivotti

Aixsponza GmbH

Producer: Julian Fischer

Line Producer: Gustaf Richter

Creative Direction: Sebastian Onufszak, Christian Tyroller

Inspire Eye Candy Animation

Art Direction: Florian Stumpe, Christian Tyroller

Artists: Jens Kindler, Simon Breithofer, Max Schwugier, Marcel Dolschon, Dominik Högn, Lukas Eberle, Stefan Voigt, Nick Zieroff

Music & Sound design: Michael Fakesch, designingsounds

Inspire Hero Artwork

Photographer: Frithjof Ohm

Production: Frithjof Ohm incl. Pretzsch

Art Direction: Julia Obermeier und Annabella Weiss

Postproduction: Dock2Studios, Hamburg

Explain Visuals & Animations

Art Direction: Sebastian Onufszak

Artists: Jens Kindler, Matthias „Tisi“ Lein, Dennis Tiege, Max Schwugier, Matthias Zabiegly

Music & Sound design: Michael Fakesch, designingsounds

Orginal Sound Design BMWi Vision Circular: Hans Zimmer, Renzo Vitale

Inform Artwork

Photographer: Oliver Maier

Postproduction: Simon Schinken

Inform Design Snippets

Director: Andreas Grassl

D.O.P.: Oliver Maier

Producer: Gustaf Richter

Cast: Selin Inan

Postproduktion: White Label Fabric, Marco Pelzel

Editing: Michael Münch

Color Grading: Florian Wolf

Musik & Sound Design: Andreas List